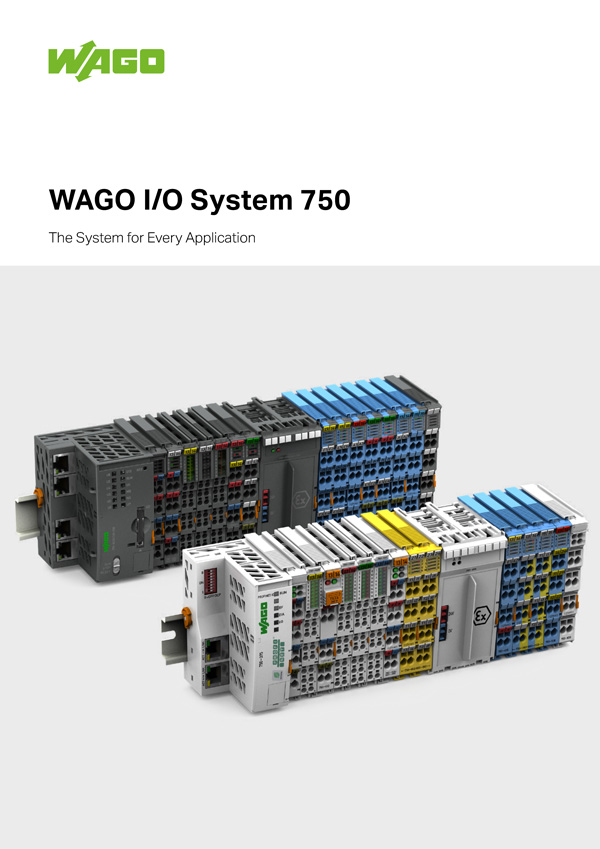

The System for Every Application

Boasting more than 500 I/O modules, programmable controllers and fieldbus couplers, WAGO’s I/O System offers all the functions required for your automation needs – and every fieldbus. The remote I/O System is the decentralised peripheral for automation technology. The tool-free wiring is intuitive for worldwide use, and the lever ensures that the contact point is always securely closed. The optional pluggable connection for the 753 Series minimises both hardware and system expenses.

- Scalable Control Solutions: Interfaces are available for any size and type of automation task – from distributed I/O nodes or stand-alone control to global networks.

- Automatic Contact: Power jumper contacts automatically provide both internal data transmission and power for the electronics, as well as potential distribution.

- Clear Labelling: Module functionality is identified via integrated and pluggable marker carriers. Terminal assignment information and technical data are printed on the side of the modules. WAGO’s WSB Marking System also allows for module- and channel-specific labelling.

- Pluggable Connection Interface: For ultimate convenience, 753 Series Modules are 100% compatible with the 750 Series and feature pluggable connectors. Thanks to the detachable wiring interface, it is easy to replace a module without removing and redoing all the existing wiring. This design virtually eliminates installation errors, enabling flexible assembly via pre-wired connectors and saving time.

- Robust Design: The WAGO I/O System is engineered and tested for use in the most demanding environments (e.g., temperature cycling, shock/vibration loading and ESD). Spring pressure connection technology guarantees continuous operation.

- Pluggable Connection Interface: For ultimate convenience, 753 Series Modules are 100% compatible with the 750 Series and feature pluggable connectors. Thanks to the detachable wiring interface, it is easy to replace a module without removing and redoing all the existing wiring. This design virtually eliminates installation errors, enabling flexible assembly via pre-wired connectors and saving time.

- Robust Design: The WAGO I/O System is engineered and tested for use in the most demanding environments (e.g., temperature cycling, shock/vibration loading and ESD). Spring pressure connection technology guarantees continuous operation.

- Scalable Control Solutions: Interfaces are available for any size and type of automation task – from distributed I/O nodes or stand-alone control to global networks.

- Compact Size: WAGO’s patented mechanical design makes extremely compact I/O nodes possible. It can accommodate up to 16 channels in a module width of 12 mm (1/2″).

- Maximum Flexibility: Each node in the WAGO I/O System can be configured to meet every channel’s requirements; additionally, various potentials and signal types are available (granularity of 1–16 channels). Digital and analog I/O modules, as well as speciality modules, can be freely mixed. Supply modules permit different voltages within the same node.

- Ease of Use: A modular, DIN-rail-mount design permits easy installation, expansion and modification of the I/O node without tools. Changes and additions are straightforward. Additionally, proven CAGE CLAMP® technology makes all field connections quick, vibration-proof and maintenance-free. Depending on the I/O module’s granularity, field peripherals can be directly wired using 1-, 2-, 3- or 4-wire technology.

Wago I/O System 750 - The Connectivity Hero

Decentralised peripherals for every application: Boasting more than 500 I/O modules, programmable controllers and fieldbus couplers, WAGO’s remote I/O system offers all the functions required for your automation needs – and for every fieldbus.

Download the WAGO I/O System 750 Brochure

The System for Every Application

The WAGO I/O System 750 brochure provides an overview of the product portfolio and its areas of application highlighting the system’s versatility and suitability for various applications. Details on modularity, ease of integration, and compatibility with different protocols and environments, information on the hardware components, performance metrics, and system architecture. You can also find examples of industries and scenarios where the system can be effectively implemented.

Shop WAGO I/O System 750/753

Decentralised peripherals for every application: Boasting more than 500 I/O modules, programmable controllers and fieldbus couplers, WAGO’s Remote I/O System offers all the functions required for your automation – for every fieldbus.

The Benefits for You:

- Fieldbus-independent – compatible with all standard fieldbus protocols and ETHERNET standards

- A wide variety of I/O modules for virtually any application

- Also suitable for use in limited spaces thanks to compact dimensions

- National and international approvals for worldwide use

- Extensive range of accessories for marking systems and connection technologies

- Fast, vibration-proof, maintenance-free CAGE CLAMP® connections