For decades, serial communication has been delivering reliable connectivity in many factory applications. Although Ethernet communication is more popular these days, a large variety of legacy equipment still relies on serial communication. As factory managers increasingly realize that OT/IT convergence optimizes operational efficiency, it is field engineers and system integrators, however, who are first in line facing the challenges of integrating older and newer systems. Fortunately, solutions such as serial device servers bridge the gap between your serial devices and modern Ethernet-based systems. However, serial and Ethernet communications remain two distinct methods of data transmission, so there may be concerns over the stability of TCP/IP networks and read/write performance when migrating from a serial to an Ethernet-based network.

Our NPort serial device servers come with what we call a Real COM driver, which creates a virtual COM port in the host computer to map the IP port on the network and allow serial devices at the edge to communicate with the host computer as if they were physically connected by serial cables, changing no serial software applications. In addition, the Real COM driver provides a rich set of advanced functions to ensure that the virtual serial port performs as close as possible to a native serial port.

In this article, we will explain how you can easily overcome the challenges of serial-to-Ethernet communication with this Real COM driver for two commonly seen applications in factories: CNC machines and Automated Guided Vehicles (AGV) monitoring.

Scenario 1: CNC Machine Monitoring

Legacy CNC machines typically use RS-232 communication. To optimize CNC machines’ productivity, getting real-time data is key so that immediate action can be taken to reduce downtime or switch manufacturing programs timely. Thus, you need to enable remote monitoring applications to control and monitor CNC machines from the control center. To achieve this, you can use serial device servers to bridge the communication between serial-based CNC machines and the Ethernet-based systems in the control center. However, data transmission between different communication methods creates uncertainty about network reliability. Besides, converting serial data over Ethernet networks can affect the performance of sending and receiving data.

How the NPort Can Help

Stay Connected With Auto Network Reconnection

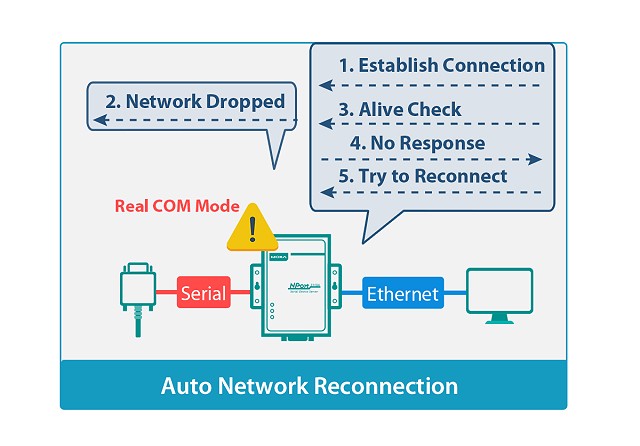

The advanced auto network reconnection function embedded in the Real COM driver ensures your CNC machines stay connected with your Ethernet-based systems. If the TCP connection drops, and our NPort serial device servers do not respond to the Alive Check packets, the Real COM driver will repeatedly try to reestablish the TCP connection so that you don’t need to close the port and reopen your software to reconnect.

How the NPort Can Help

Enhancing Transmission Performance With Tx Mode and Fast Flush

To achieve the operation performance as close as possible to a native COM port, the Real COM driver provides functions that enhance transmission performance for your CNC machine monitoring applications. First, our Tx Mode function features Hi-performance mode, allowing the NPort driver to notify the application program once the data has been sent out. This way, you can enhance the transmission performance and provide better throughput compared to classical mode, in which the NPort driver will only notify the application program once it has received confirmation from the NPort.

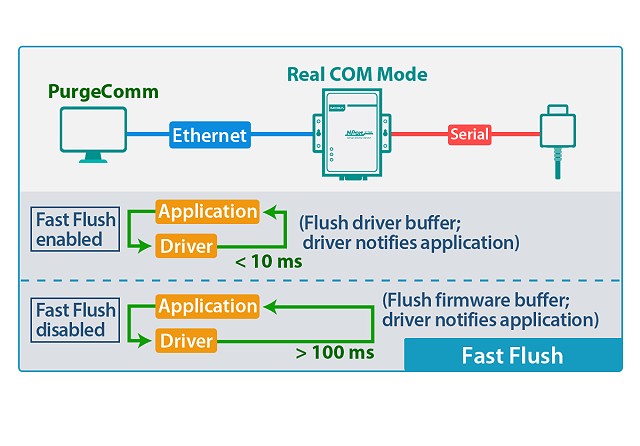

Fast Flush is a function that we have designed especially for Windows operating systems. In some applications, the user’s program uses the Win32 PurgeComm() function before it reads or writes data. If your program uses this PurgeComm() function, the NPort driver will keep querying the NPort’s firmware to make sure no data is queuing in the NPort firmware buffer before flushing the local buffer, which results in longer response times. To accommodate applications that require a faster response time, our Fast Flush function directly flushes the local buffer without querying the NPort firmware, enhancing transmission performance.

Scenario 2: AGV Monitoring

AGVs automate lifting and transporting tasks in a manufacturing facility or warehouse, thus increasing efficiency and reducing labor costs. Usually, magnetic tape guides AGVs along their path, which the AGVs follow with their built-in guide sensors (e.g., RFID). The application software constantly sends a location request to the AGV to verify its current location every 50 ms until a response is received. Once the location has been determined, the software sends task commands. Many application programs have a specific timeout limit for sending and receiving data. If the controller on the AGV cannot reply to the location request on time, the application will continuously send out the request, resulting in inefficient overall communication.

How the NPort Can Help

Control Transmission Time With Data Packing and Force Transmit

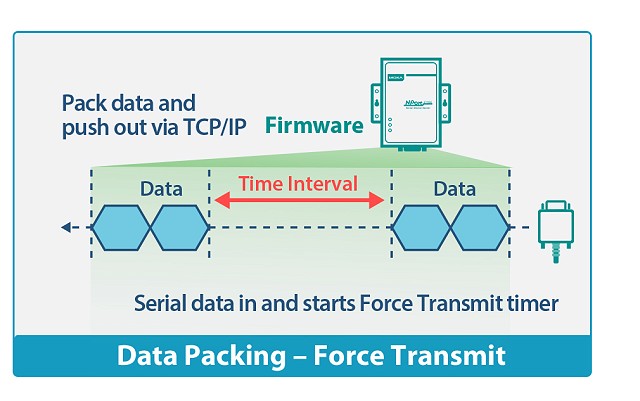

Our NPort Real COM driver supports the Data Packing function that determines when or how the serial data should be packed for transmission to ensure smooth communication in your AGV operation. Your serial data can be packed by specifying packet length or when a special character is detected. If the data packet does not have rules, or you still want to send incomplete data packets, the Force Transmit function allows you to preset a maximum time interval to wait for a complete serial data stream. The interval timeout between characters defines this function, forcing the firmware to pack serial data into the same data frame during the specified time. By enabling this function, the NPort serial device server transfers data stored in the buffer via TCP/IP only if the internal buffer is full or the inter-character interval times out.

Our NPort serial device servers provide a variety of functions for different operation modes to meet your demands in industrial applications. You can download our guide to learn more about other functions. In addition, our NPort serial device servers feature security functions and a variety of OS driver support to ensure your serial devices can be easily and securely connected to modern systems.