This new technology from LAPP is available now. If you think you would benefit from this, please contact our customer services team sales@ecsnz.com to discuss your application further.

It's what's inside that counts

By Frank Hörtnagl, Product Manager at U.I. Lapp GmbH

Cables sometimes have to stand up to a lot. For instance, wherever they are required to have a high level of resistance to notches, cuts and abrasion in indoor and outdoor use in harsh environmental conditions and manufacturing processes, or equally in particularly oily machinery and plant areas, as well as at low temperatures or under UV or glaring sunlight. In such applications, cables with a conventional PVC outer sheath quickly reach their maximum limits. That is why PUR cables are normally used where cables have to withstand tough conditions. Specially selected sheath compounds made of resistant polyurethane ensure the necessary robustness and durability.

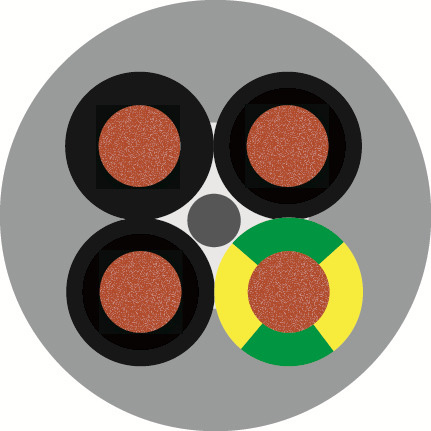

However, the manual and machine processing of these PUR cables for heavy duty use is considerably more complex. The sheath plastic is usually "press" extruded along the conductor bunch under high pressure in the production process of power and control cables. In the process, the gaps - known as interstices - are completely filled with sheath material between the cores of the outer stranding layer. If the polyurethane material is very robust, cut-resistant and notch-resistant, the filled interstices can make it more difficult to strip the outer sheath, as they cannot be captured by the blade when cutting the circular sheath. The blade setting of the processing equipment must therefore be precisely adjusted in order to cut the outer sheath as deeply as possible. However, it is not uncommon for the core insulation to be damaged in the process. On the other hand, an insufficient cutting depth presents the risk that during the removal process, there is stringing or fraying of the sheath, or that is torn off under high tensile forces in an uncontrolled manner as the blades slip off and do no more than scrape along the surface of the sheath. The consequences are often extensive manual post-processing, machine downtime and a preventable waste of material - and that costs additional time and money.

In order to avoid these problems, the Stuttgart based Lapp Group has now launched the two control cables ÖLFLEX® 408 P and ÖLFLEX® 409 P with increased mechanical and chemical resistance for harsh conditions, which enable more efficient and reliable stripping thanks to an integrated, interstice filling functional layer on a special PVC base. Lapp has developed a completely new production method to do this.

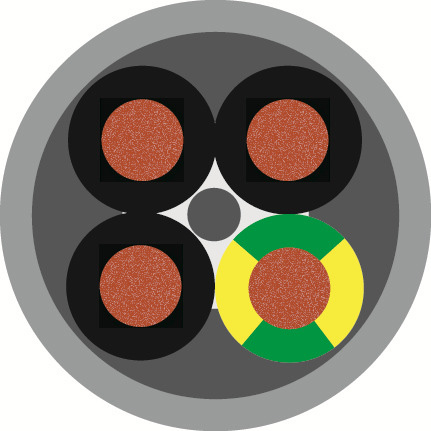

Special co-extrusion technology is used for the sheath production of ÖLFLEX® 408 P and ÖLFLEX® 409 P, which combines the abrasion-resistant and notch-resistant polyurethane outer sheath with a further interstice filler functional layer made of special PVC. PUR and PVC have very different material and elongation at break properties. The polyurethane material is chemically and mechanically highly resilient and thus enables the cable to be used for a wide application range. The underlying functional layer made of polyvinyl chloride serves as a interstice filler and a puffer between the outer sheath and the core stranding and thanks to its optimised tear characteristics can counteract typical problems during sheath processing. This enables the cut depth to be reduced in order to protect the core insulation. That means stringing, fraying sheaths and poorly processed power cables are now a thing of the past. The separation and removal of the sheath - whether by machine or manually - is therefore considerably easier.

The user thus benefits from several benefits simultaneously: Improved stripping characteristics, reduction of damage to core insulation, less subsequent manual processing and reduced material waste. This results in time and costs savings

The grey ÖLFLEX® 408 P with VDE registration is an all-rounder in mechanical processing. It is abrasion and notch-resistant, highly oil-resistant, resistant to hydrolysis and microbes, and flexible at low temperatures up to minus 15°C. The ÖLFLEX® 409 P, tailored for the North American market with a black outer sheath colour, offers similar features and is also flame-retardant in accordance with international IEC,UL and CSA flame tests. Both power cable solutions have the new interstice filler functional layer and are thus also an interesting alternative for installers who need to strip a lot of cables in the shortest possible time.

The cable design and the assured properties of the new ÖLFLEX® polyurethane cables have been tested and certified by the German VDE test institute and UL (Underwriters Laboratories). In addition, the products are subjected to regular factory surveillance in order to guarantee the highest quality standards.

The development team of the new ÖLFLEX® 408 P and ÖLFLEX® 409 P with integrated functional layer was recently awarded the Eddie Lapp award. The award is an internal Lapp prize which is presented every year to honour outstanding innovations within the Lapp Group. The prize is named after Siegbert E. Lapp, Chairman of the Supervisory Board of Lapp Holding AG.

The ÖLFLEX® 408 P and ÖLFLEX® 409 P control cables, with increased mechanical and chemical resistance for harsh conditions, can be reliably stripped thanks to their integrated interstice filler functional layer.

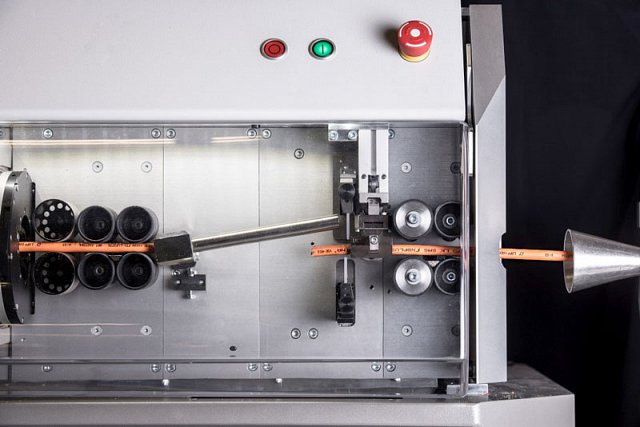

The blade setting of processing machines normally has to be precisely adjusted to cut into the outer sheath as deeply as possible. Thanks to the interstice filler functional layer, the cut depth can be reduced.

Co-extrusion technology is used for the ÖLFLEX® 408 P and ÖLFLEX® 409 P. The interstice filler functional layer is inseparably connected with the polyurethane outer sheath.

The outer sheath of control cables is normally press extruded with interstice filler.

Article Source: http://www.lappkabel.de/presse